- About us

- Company details

Urbinati S.r.l., founded in 1980 and headquartered in San Mauro Pascoli (Italy), is a global leader in the design and manufacture of advanced automation systems and equipment for professional nurseries and horticulture. With over four decades of experience, Urbinati has built a reputation for innovation, reliability, and customer-oriented solutions that meet the evolving needs of growers worldwide.

The company offers one of the most comprehensive product ranges in the sector, covering all key stages of nursery operations: sowing, germination, transplanting, irrigation, substrate handling, and logistics. From individual machines to fully integrated lines, Urbinati develops scalable solutions that can be customized to fit the specific requirements of small, medium, and large-scale producers.

Product Portfolio

Sowing Machines & Germination Systems – High-precision seeders (drum and vacuum technology), covering heads, vermiculite distributors, and automated germination chambers.

Transplanting Machines – Flexible and high-speed transplanters for seedlings, cuttings, and plugs, with customizable grippers and layouts.

Irrigation Systems – Overhead irrigation booms, ebb-and-flow benches, misting systems, and fully automated watering solutions for uniform and efficient plant growth.

Soil & Substrate Handling – Mixers, bale breakers, soil hoppers, dispensers, and filling machines for pots, trays, and containers.

Potting & Seeding Lines – Automated lines combining potting machines, conveyors, tray fillers, seeders, and irrigation for large-scale nursery operations.

Logistics & Handling – Conveyor belts, buffer systems, stacking/unstacking units, and customized layouts to streamline production flow.

Accessories & Digital Solutions – IoT-ready control systems, data monitoring, and smart integration tools for real-time management.

Innovation is at the core of Urbinati’s strategy. The company invests continuously in R&D to develop new technologies that increase efficiency, reduce costs, and support sustainable nursery practices. Urbinati machines are designed to optimize energy and water use, minimize waste, and guarantee consistent quality standards.

A strong focus on digitalization and smart integration allows Urbinati equipment to be connected, monitored, and managed through modern IoT solutions, enabling growers to collect data and improve decision-making in real time.

With an international presence in more than 80 countries, Urbinati relies on a network of qualified dealers and service partners to ensure timely support and technical assistance. The company’s global footprint is supported by strong partnerships, continuous training, and a customer service team committed to providing reliable after-sales support.

Urbinati’s commitment extends beyond technology. The company strongly believes in building long-term relationships with its clients, based on trust, transparency, and shared growth. Thanks to this approach, Urbinati has become the preferred partner for many of the world’s most advanced nurseries, helping them achieve higher productivity and competitiveness in increasingly challenging markets.

Key strengths of Urbinati:

Over 40 years of experience in nursery automation.

Complete product portfolio covering all nursery processes.

Continuous investment in R&D, innovation, and sustainability.

Customized solutions for nurseries of all sizes.

Global presence with machines installed in 80+ countries.

Strong dealer and service network ensuring reliable support.

Today, Urbinati stands as a symbol of Italian excellence in horticultural automation, combining engineering expertise, technological innovation, and customer focus. The company continues to look ahead, anticipating industry trends and developing solutions that enable nurseries around the world to grow smarter, faster, and more sustainably.

Year of establishment:

1998

Number of employees:

FROM 100 TO 499 EMPLOYEES

Annual turnover:

between 15 and 25 million Euro

Reference year of turnover:

2020

Export turnover:

From 15 to 50 million Euro

Activities:

Manufacture of agricultural and forestry machinery

Manufacture of other agricultural and forestry machinery

Manufacture of other agricultural and forestry machinery nec

Repair and maintenance of other machinery used in agriculture and forestry

Activities of agents involved in the wholesale of agricultural equipment

Wholesale of agricultural machinery, equipment and supplies

- Contact Information

- Business Proposals

Company:

URBINATI S.R.L.

Address:

VIA DELLA LIBERAZIONE 18

City:

SAN MAURO PASCOLI (FC)

Zip Code:

47030

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

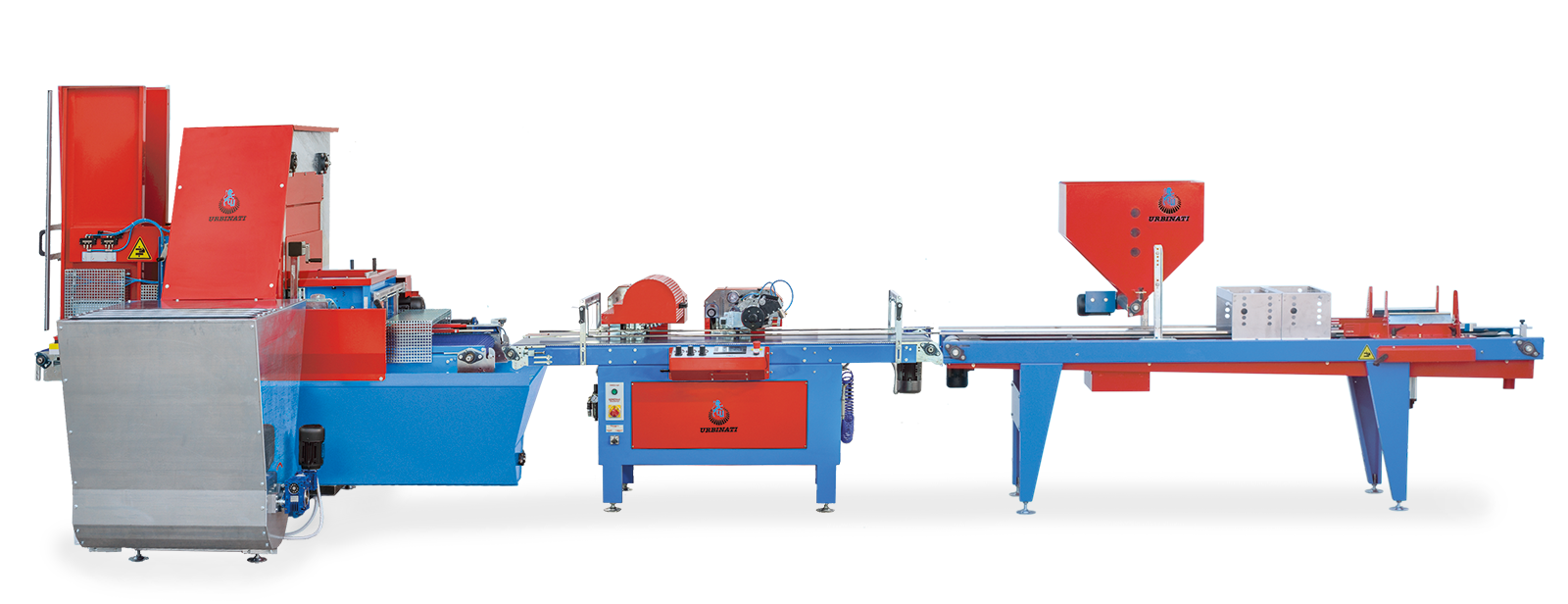

SEEDERS & SEEDING LINE

Urbinati manufactures customized seeding lines and automatic seeders working in close contact with the customer, in order to best fit their requirements. The nursery modular solutions offered by our company, adapt to any seeds and trays, and are customized according to your business needs.

Our customizable modular machines are characterized by the possibility of selecting multiple sowing solutions such as: automatic drum seeding lines, row seeding lines or plate seeding lines. The drum seeding lines can be accessorized with single, double or triple sowing heads. Trying to meet the different needs of our customers we offer ad hoc solutions for production with non-standard seeds such as our volumetric seeder suitable for large seeds.

To complete the seeding lines and seeders we provide a series of final units such as: integrated peat cover units, watering units (drilled bars or sprinkling watering units) and stacking units.

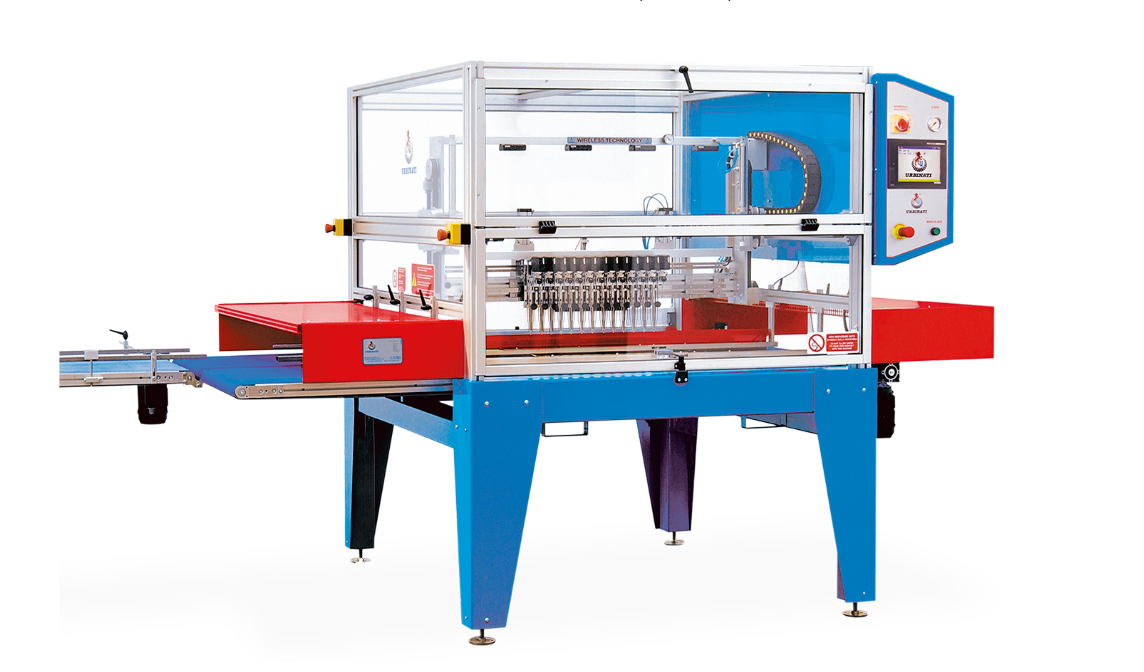

TRANSPLANTER & TRANSPLANTING LINE

In the transplantation sector we offer a series of automatic nurseries transplanters with patented and programmable wireless grippers.

Urbinati’s nurseries robotic trasplanters automatic nurseries transplanters allow multiple seedling transplanting from one trays to another thanks to the motorized wireless grippers and easily removable and equipped with exclusive flat profile needles.

Thanks to the touch-screen control panel it is possible to set the transplanter according to your needs can be set the side pick-up of the plant, the multiple transplantation in pots and much more.

The seedling transplant configurations are customized according to the customer needs who can choose between machines with single or double row grippers up to a maximum of 80 grippers on double row and a production up to 56,000 plants-hours transplanted.

MOBILE IRRIGATION SYSTEM

Urbinati mobile irrigation systems automate and make efficient the indoor and outdoor irrigation process in greenhouses and nurseries.

Urbinati irrigation booms, both indoor and outdoor, can be single or double suspended rail, in both cases the ability to customize, through a remote control, programming with interzone irrigation cycles makes them extremely flexible and adaptable to every need.

In addition, through a simple interface, you can control the direction and speed of the irrigation bar so as to save resources and time. Our irrigation booms are manageable from a single and easy-to-use remote control, that can handle up to 240 mobile irrigation systems.

GERMINATION CHAMBER

CELLA is a germination chamber that is insulated from external temperatures, in which the optimal conditions to stimulate the development of plants are recreated, thus shortening the germination time normally required for the seed planted to mature in an uncontrolled environment.

The possibility of reducing these times, combined with the yield achieved by the seeds used, make the germination chamber an essential tool for maximising yield: resources used are not wasted and the new production cycle can be started in advance thanks to the time saved on the previous one.

The insulated chamber is designed and made to measure according to the customer’s requirements and can be installed both inside and outside the greenhouse.

TRAY WASHER

The LAV10 automatically washes and disinfects trays and containers in general, of various shapes and sizes.

Once positioned at the entrance to the machine, the containers advance inside it automatically, by means of the support belt that runs on the bottom. In the washing chamber, the containers containers are water sprayed by high pressure nozzles: it can be easily removed to facilitate cleaning and, if necessary, for replacement.

After washing with water, the containers can move through an additional treatment to eliminate any pathogenic factors: they can be treated with chemicals, suitably diluted, or with UV lamps, capable of eliminating photosensitive bacteria. In both cases, all that is required is integration of the standard model with the treatment tunnel.

Additionally, when connected to an input feed belt and an output accumulation belt, the automatic tray-washer can be transformed into a complete and autonomous WASHING LINE, with great results in terms of production and efficiency.