- About us

- Company details

SAPORITI is an Italian Company with a lot of experience which design, manufacture and install machine tools since 1946.

All our machines are constantly kept up to date with the latest technology available on the market and always offering a customized high performance, quality, reliable machines.

The export is more than 90% especially in Europe, America and China.

Today we are world well known leader in the manufacturing of:

- Ball valve grinding machines suitable for the grinding of ball of valves in steel or coated by satellite, ceramics CBN, Nickel-Boron alloys or others materials. These machines arein different ranges from 1” to 72”.

- Thread milling and whirling machines for screw manufacturing. These screws are for plasticizing machines as extruder and injection moulders, pumps and compressors. We have models with end mills, disc cutters and whirling units. We have our own screw software SAPOVITE to assist with programming.

- Deep-hole drilling-boring-honing-rolling machines. There are different models with rotary workpieces for single holes or fixed also for the complete manufacturing of twin screw barrels. There is the possibility to have controlled boring tools for internal profiling (bottle boring)

The Company philosophy, from the beginning, is giving high quality machines with the best quality material and technology at the best price to give productivity advantages and to assure our Customer to be really competitive in the Market.

Year of establishment:

1971

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2019

Export turnover:

From 750.000 to 2.5 million Euro

Activities:

Manufacture of metal forming machinery and machine tools

Manufacture of metal forming machinery and machine tools for metal work

Manufacture of other machine tools

Manufacture of other special-purpose machinery

- Videos

- Catalogue

SAPORITI production range

Saporiti thread milling machines for screws and twin screws

Deep Hole drilling - pull/push boring - honing machines Saporiti

SAPORITI PV Ball Valve grinding machines from 1" up to 100" OD

- Contact Information

- Business Proposals

Company:

" SAPORITI S.R.L. "

Web site:

Address:

VIA DEI PATRIOTI 58

City:

SOLBIATE OLONA (VA)

Zip Code:

21058

Social media:

Tag:

No business proposals uploaded

- Map

SAPORITI PLUS 400 thread milling machine for plastic and rubber extruders and injection molders screws and twin screws manufacturing

SAPORITI THREADER MACHINES for SCREWS since 1970: the SAPORITI PLUS 400

The Saporiti Company is an italian machine tools manufacturer located in Solbiate Olona since 1946 and from ‘70 starts the production of milling machines for screws. The first models was mechanical but in the years there was the application of CNC as the screws are more and more complicated also with variables pitches and cores and with cams ond lobes.

With the new generation machines all the screws and twin-screws can be realized also with spline shafts and with any thread shape. These screws are for plastic or rubber extruders and injection molders, for pumps, compressors or convey. There are machines with heads for end mills, disc cutters or whirling units.

The most popular model is the SAPORITI PLUS 400 a threader machine suitable to manufacture screws and twin screws with diameters up to 250 mm and length from 2000 mm up to 8000 mm with end mills.

The strong electro-welded steel bed is realized to conform customer request and workpieces length needs. It is 45° inclined to allow the better operator view of the working area and to facilitate the chips and coolant falls in the chips conveyor positioned under the milling head.

The chips conveyor is in a structure which hold the safety doors with wide windows with safety glasses suitable to protect the operator and the environment but allow a good view and the easy workpieces loading.

The CNC is a SIEMENS 840 SL and can control 5 axis three linear and the two spindles.

The milling head has vertical movement (Y axis) and it is equipped with a ISO 50 or HSK 100 hydraulic spindle for rapid face cutter change. The maximum spindle speed reached the 5000 rpm with a cutter motor power of kW 22. This motor is sealed to warrantee the best performance in less noise generated and in the optimization of power loss. There is a separate chiller for the cooling of the circulating fluid.

On the milling head carriage on a slide there is a self-centering hydraulic follow rest with long blades suitable to hold the threads lengths. This rest has the capacity to hold a wide range of diameters automatically keeping in the machine center. Available working ranges for the following diameter ranges in mm 15-150; 20-180; 30-240, 35-250. Available also blades with fitting to be inclined for outer tapered screws. This rest is positioned on a support and can be moved 100 mm left and right compared to the milling axis. This movement is normally manual by hand wheel but can also be motorized as an option.

The rest position is perfect to be in contrast with the cutting force power.

Other available optional are :

- A 12-position tool changer

- The possibility to have the cutters with internal cooling system.

The new generation Sandvik tools thank at the great positioning precision of the C spindle axis allow the possibility to work also the spline parts.

These SAPORITI PLUS 400 thread milling machines are perfect to work small medium sizes screws and twin screws with any type of thread or mixing sections.

The PLUS 400 models can use the SAPOVITE software developed by Saporiti and suitable for the easier screws programming. This software is very open to the programmer and allow the programming of also very complicate screws and twin screws. The tools choice depend by the programmer and guarantee the benefits also when manufacturing one screw only. The program library memory is almost infinite.

All the threader machine Saporiti can be placed in a 4.0 factory contest.

Additional information at www.saporitimachines.com or apply at info@saporiti.it.

Web site

http://www.saporiti.it

Deep Hole Drilling - pull/push Boring - Honing machine SAPORITI FL 500 suitable for the complete manufacturing of twin screws barrels

The SAPORITI FL500 drilling-boring-lapping machine series has fixed workpiece and has been expressly designed for the complete and precise machining also of twin screw barrels of plasticizing chambers.

The unique advantage of these machines is to produce twin barrels fast and with great accuracy. The machining procedure consist in the deep hole drilling, pull or push bore and hone the first hole, then, when these operations are completed, the machine automatically shift the barrel position to machine the second one.

The machine feed movements slide on precision roller bearings which provide high precision, good surface finishing and long machine lifetime. Main features of this special boring machine is the workpiece setup on two carriages with controlled transversal slides (X1 and X2 axes).

The carriages are equipped with strong rests to hold workpieces with diameters from 100-500 mm.

These boring machines have separate tanks for cutting fluid from 3000 up to 5000 liters following the machine versions and pumps with control for variable flow.

A relevant chips conveyor remove the chips from working area.

The CNC Siemens 840D SL controls 5 axes and facilitates the programming of solid drilling, push and pull boring and lapping operations also thanks the Saporiti customized masks available in any language on the console.

These machines are in different versions from 2500 mm up to 5000 mm length and Outer max. Diameters from 400 mm up to 600 mm.

Also available version for taper holes or with rotary workpieces PR also with Bottle Boring option.

Saporiti manufacture machine tools since 1946 and machines for barrels from 1974. More information in the web www.saporiti.it

Web site

http://www.saporiti.it

SAPORITI PV 500 Ball Valve Grinding machine especially studied for metal to metal seats balls and coated ones up to 565 mm OD (23.5")

The ball valve grinding machine SAPORITI PV500 is an extremely innovative machine.

It was especially studied to work balls for metal to metal seats ( as allow Roundness accuracy better than 0.01 mm 0.0004” and Roughness accuracy better than Ra 0.2 µ - AA 8)

Construction layout: the grinding wheel head is 60 degrees inclined as to the horizontal surface to give the operator a better view of the machining operations and to let the coolant easily fall down; the machine bed is a strong fabricated structure, its shape is designed to easily convey the grinding swarf to a large filter thus keeping the machine clean, which is very important during grinding; the machine case is completely made of stainless steel to avoid damage to filters caused by paint residues.

Technical solutions: motors with closed cooling systems to reduce noise and failures caused by large quantities of coolant; guide roller pads for high precision and best surface finish; CNC-controlled Y axis with micrometric movement; Renishaw tracer for perfect centering of the grinding wheel on the workpiece.

Suitable customized mask on the CNC help and guide the operators during ball valve grinding procedure

Web site

http://www.saporiti.it

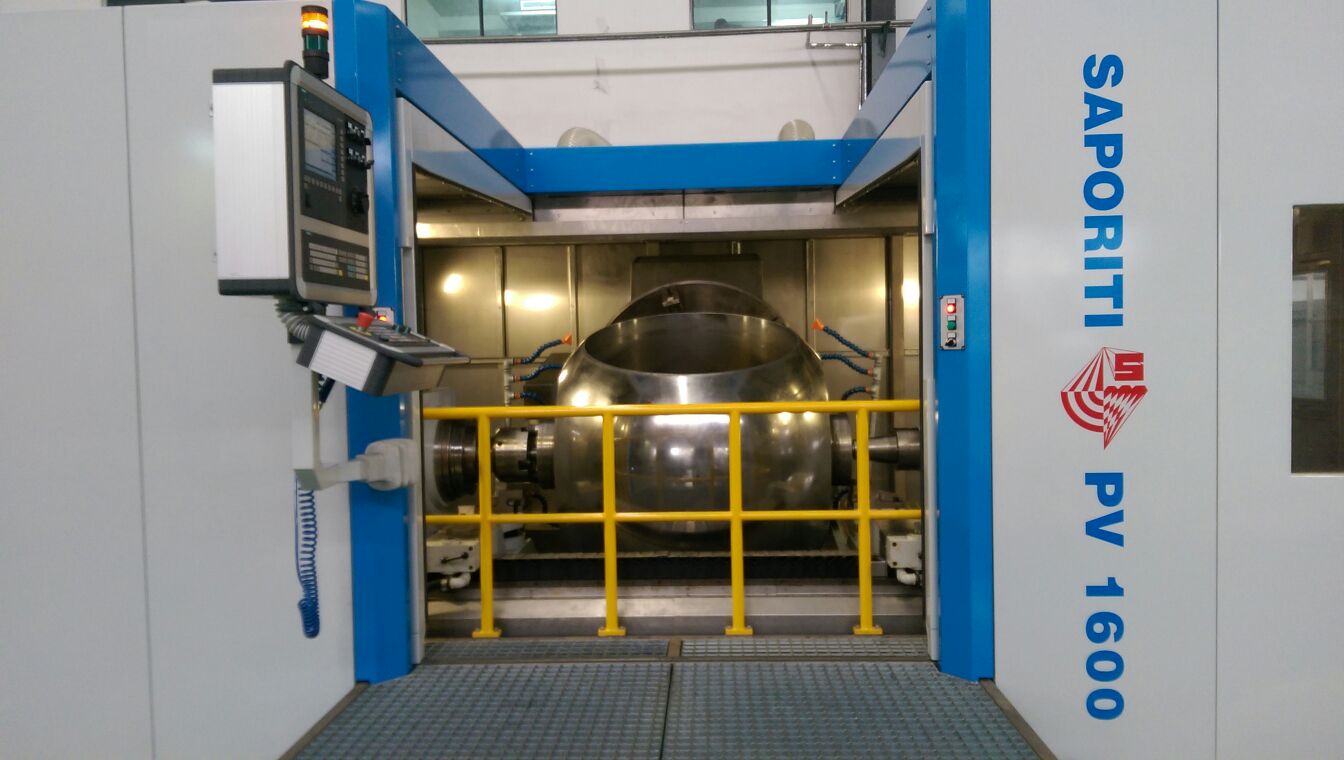

Ball Valve Grinding machine SAPORITI PV 1600 for coated and metal to metal seated balls up to 1600 mm OD (63")

SAPORITI srl from Solbiate Olona Italy (www.saporitimachines.com) manufacture Ball Valve Grinding machine since more than thirty years.

The latest Ball Valve Grinder is the model SAPORITI PV1600. This machine is suitable for the grinding of steel and coated balls up to 1600 mm (63") OD especially with metal to metal seats.

Main features of this machine are:

- the rigid structure,

- the using od sealed motors for less noise, less power consumption and less maintenance of the machine

- the using of roller guideways to assure the best accuracy and the best finishing surface of the workpieces;

- the grinding wheel inclination to allow a better view of the operator and the easier flow of the coolant.

- CNC 840 Siemens which controls at least 3 linear axis and 2 rotary

- a Renishaw probe to center the workpiece and the grinding wheel.

- a CNC controlled vertical Y axis for the micro movement of the grinding tool to allow the perfect centering

- a customized software to allow the operator the easier centering between tool and ball and the faster programming of grinding cycles.

- the adjustable tool holders. Only one wheel can be used for different diameters and can fit standard grinding pads or diamond discs.

- the presence of relevant filters for coolant and for air.

- The possibility to work steel balls and coated balls

Then this machine has a very rigid structure very important to avoid vibration due at the hole in the balls and a big covering frame in stainless steel to protect operators and to contains the working fluids which are really a lot an corrosive in the grinding machines.

The grinding wheel are big then it is important that can be regulate to cover a wide range of balls diameter to avoid the continuous changing of them. The same tool holders allow the fittings of standard grinding pads and of diamond discs. These discs are necessary to grind coated valves (by Stellite, ceramic, alloys of chrome, nickel also with boron…..).

The CNC Siemens Control also the micro movement of the vertical Y axis of the grinding tool to allow the perfect centering between tool and ball to reach the workpiece roundness highest accuracy. This position is defined by the Renishaw probe.

The sealed motors used on this machine produce less noise, allow less power consumption and less maintenance of the machine to conform to the latest energy requirements. Saporiti developed a customized helping CNC masks to drive the operator for an easier centering between tool and ball and the faster programming of grinding cycles.

The good surface finishing are also warrantee by the presence of relevant filters for coolant and for working air which guarantee the best fluid cleaning.

High accuracy in roundness (better than 0.01 mm) and surface finishing (better than Ra 0.2) can be obtained by these grinders.

This machine belongs to the series PV2000 which include machine suitable to grind balls up to 2500 mm OD.

Web site

http://www.saporiti.it

THREAD MILLING MACHINE SAPORITI SAR 500 for pumps and compressors screws milling up to 500 mm (19.5") OD by disc cutters

The SAPORITI SAR 500 is a CNC machine for the fast manufacturing of pump and compressor screws by Disc Cutters with surprising features.

This machine has 5 CNC-controlled axes: two linear, one rotary and two spindle.

The SAPORITI SAR 500 can easily machines workpieces up to 500 mm in diameter with cutters diameters up to Ø 440 mm. Maximum workable length: 1200 mm. The milling head tilting axis reach ± 50°.

The machine is equipped with CNC Siemens 840D SL and motors with forced liquid cooling to reduce power composition and machine noise level.

The linear axes run on precision roller bearings. The positioning accuracy is guaranteed also by the use of linear encoders.

The chattering noise, which is typical of working with disc cutters, is cut down in this machine thanks a special device patented by SAPORITI Company.

It is possible work without problem also extremely hard steels such as 17-4-PH (with extremely high hardness HRC 34-HB300) with pass depth even of 80 mm. In this case cutters with coated tips are use. For normal steel can be use also disc cutters in solid carbide steels or brazed.

The machines rigidity allows for high chip removal and very good surface finishing.

To cover a wide range of working diameters this machine can be equipped by two hydraulic rests with long blades easily interchangeable. The upper blade has hydraulic block to allow the fast traveling movement and assure the best holding during milling.

The CNC allow also the easy execution of pumps and compressors screws profiles by SAPORITI’s especially developed customized working mask “customer friendly” to help the operator in machine using and programming.

There are available others version for smaller diameters.

SAPORITI (www.saporitimachines.com) Company manufacture machines tools since 1946 and it is specialized in the manufacturing of CNC threader machines for the milling of extruder screws and twin screws since 1970 and is able to help customer to choose the more suitable machine for their working needs.

Web site

http://www.saporiti.it